Electrifying Shift: Global Auto Giants' Pivot to EV in China

Redefining the Roadmap: Lessons from China's EV Surge for Automotive PMs

With global auto giants like Volkswagen and Nissan drawing critical lessons from China's electric vehicle (EV) industry, we're at a pivotal juncture in automotive manufacturing. This shift isn't just geographical; it's a complete overhaul of the EV production paradigm. As hardware and software product managers, our response to this transformation will shape the future of automotive technology. Let’s explore actionable strategies and insights for navigating this landscape. 🌐

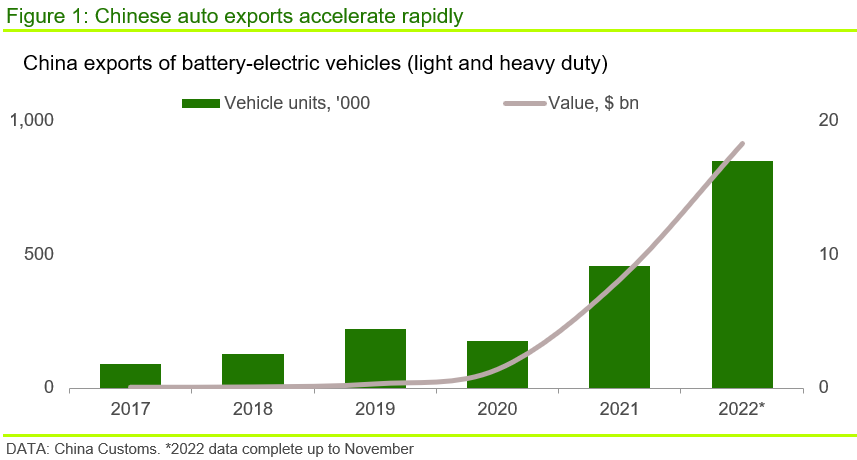

China's EV Ascendancy: More Than Just Speed

China's rapid production rates and advanced EV technologies offer a wealth of lessons, especially in terms of agility and innovation. For hardware PMs, this means a reevaluation of supply chains and manufacturing processes. Software PMs must pivot towards more integrated and advanced digital solutions, aligning with the evolving complexities of EVs.

Tangible Strategies for PMs

Agile Development Processes: Adapt to the fast-paced, iterative approach seen in China’s EV production. This entails a shift towards rapid prototyping and shorter development cycles for hardware PMs. Software PMs should focus on flexible, modular software architectures that can quickly adapt to changing hardware specifications.

Localized Supply Chain Integration: Embrace a more localized and responsive supply chain strategy. For hardware PMs, this means developing closer ties with regional suppliers for quicker turnaround times. Software PMs should explore partnerships with local software developers and digital solution providers to tap into regional insights and innovative practices.

Deep Dive: Technological Synergies and Production Efficiency 📈

Analyzing how Chinese EV manufacturers optimize the interplay between hardware components and software systems can reveal new efficiencies. This analysis helps identify areas where hardware and software PMs can collaborate more effectively to reduce time-to-market and enhance product functionality.

Workshop Idea: Cross-Functional Collaboration

Organize workshops that bring together hardware and software teams. Focus on cross-functional collaboration for developing integrated EV solutions, from battery technology and power management systems to user interface and connectivity features.

Checklist for Navigating the EV Shift ✅

Competitive Analysis: Conduct thorough research into China's EV market. Identify key technological trends, consumer preferences, and production methodologies that can be adapted to your context.

Tech Partnership Exploration: Actively seek partnerships with tech companies that specialize in EV-specific innovations, such as advanced battery technologies or AI-driven vehicle software.

Sustainability and Compliance: Ensure your strategies align with global sustainability standards and local regulatory requirements, particularly in the context of emissions and battery disposal.

Final Thoughts: Seizing the EV Opportunity

The global shift towards Chinese EV manufacturing practices is an opportunity to redefine automotive production. By strategically adapting our hardware and software approaches, we can drive innovation, enhance efficiency, and meet the rapidly evolving demands of the EV market.

Ready to electrify your approach to automotive manufacturing?

Signing off with a reflection: How will you leverage these insights to steer your projects towards success in the EV era?